TECHNO STEAM TRAPS

Innovative Steam Traps and Condensate Recovery Systems

INVERTED BUCKET STEAM TRAPS

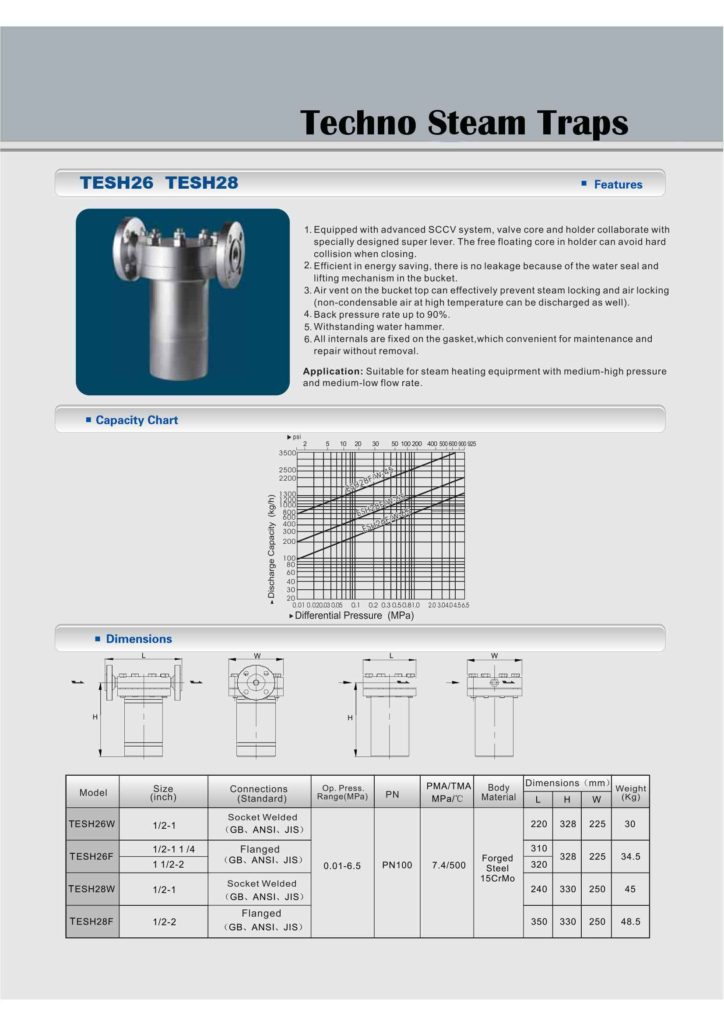

TSH26 TSH28

Detailed Product Description

High Pressure Inverted Bucket Steam Traps Forged Steel

Quick Details:

Model: TESH26, TESH28

Material: Forged Steel

size: 1/2″-2″

Temperature of Media: High Temperature

Working Media: Steam, Condensate Water

Model Number: | TESH26, TESH28 |

Standard or Nonstandard: | Standard |

Structure: | Inverted Bucket Steam Trap |

Pressure: | High Pressure,0.01 – 6.5 MPa |

Power: | Automatic |

Material: | Forged Steel |

Temperature of Media: | High Temperature |

Media: | Steam, Water |

Port Size: | 1/2″ – 2″ |

Body Material: | A182 F11 |

Connection: | Flange & Socket Welded |

Specifications:

Inverted Bucket Steam Trap

Water Seal & No Steam Loss

Air Vent on the Bucket Top

High Back Pressure

New SCCV system

Internal Check valve

Design Pressure: PN160, PN250

Pressure: 0.2 – 14 Mpa

Material: Forged Steel A182 F11

Temperature: 500 ℃

Working Media: Steam, Condensate Water

End Connection: Flange, Socket Welded

Inverted Bucket Steam Trap / Mechanical Steam Trap

TER34, TER35:

- With main valve and sub-valve double ported differential pressure mechanism and SCCV system, the steam trap is small in size and large in capacity.

- Open float withstands water hammer; air vent on the bucket trap’s top can prevent steam locking and air locking effectively.

- Effective preventing leakage because of the water seal inside valve.

- Valve seat is on top of the trap’s body, when the valve seat opens, the impurity and condensate will be discharge under the force of differential pressure.

- Internal check valve has light influence on capacity.

- Back pressure rate up to 90%.

Application:

This inverted bucket steam trap is suitable for high pressure, over heated situation and heating equipment which producing a large amount of condensate.