TECHNO STEAM TRAPS

Innovative Steam Traps and Condensate Recovery Systems

BALL FLOAT STEAM TRAP

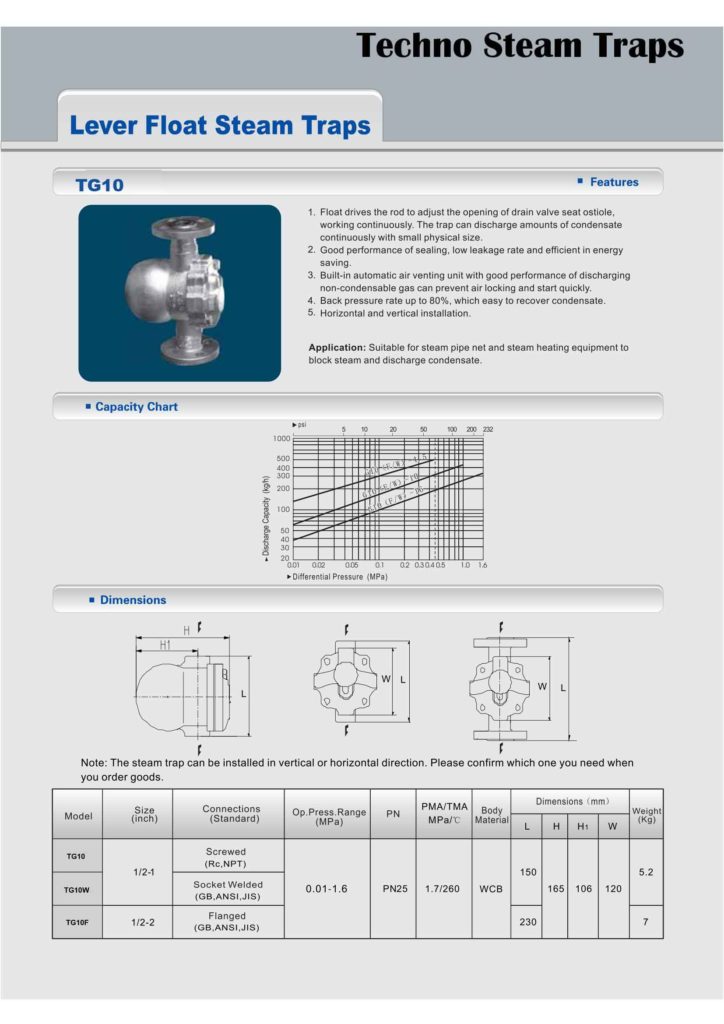

TG 10

Detailed Product Description

Lever Ball Float Steam Trap PN25 G10

Quick Details:

Model: TG10

Design Pressure: PN25

Pressure: 0.01 – 1.6 Mpa

Material: Casting Steel WCB

Temperature: 425 ℃

Working Media: Steam, Condensate Water

Size: 1/2″-2“

Model Number: | TG10 |

Standard or Nonstandard: | Standard |

Structure: | Free Float Steam Trap |

Pressure: | Low Pressure,0.01 – 1.6 MPa |

Power: | Automatic |

Material: | Casting Steel WCB |

Temperature of Media: | Up to 425 Deg. C |

Media: | Steam, Water |

Port Size: | 1/2″ – 2″ |

Body Material: | WCB |

Connection: | Flange & Screw & Socket Welded |

Specifications

Ball Float Steam Trap

Discharge Continuously

Small Size Large Capacity

Built-in Air Vent & Strainer

High Back Pressure Rate

Design Pressure: PN25

Pressure: 0.01 – 1.6 Mpa

Material: Casting Steel WCB

Temperature: 425 ℃

Working Media: Steam, Condensate Water

End Connection: Flange, Screw & Socket Welded

Ball Float Steam Trap / Float Steam Trap / Mechanical Steam Trap

TG10:

- Float drives the rod to adjust the opening of drain valve seat. The trap can discharge amounts of condensate continuously with small physical size.

- Good performance of sealing, low leakage rate and efficient in energy conservation.

- Built-in automatic air venting unit with good performance of discharging non-condensable gas can prevent air locking and start quickly.

- Back pressure rate up to 80%, which easy to recover condensate.

- Horizontal and vertical installation.

Application:

this lever float steam trap is suitable for steam pipe net and steam heating equipment to block steam and discharge condensate.

Introduction to lever Float Steam Traps:

Valve in the steam trap can be opened and closed by utilizing lever and amplification device. In the valve float connects lever, which drive valve core. The float can adjust opening of trap automatically. Built-in automatic air vent can prevent air locking and rapid start-up is provided. There is no steam leak for the water seal in valve.