TECHNO STEAM TRAPS

Innovative Steam Traps and Condensate Recovery Systems

THERMOSTATIC STEAM TRAP

TB - GE

Detailed Product Description

Casting Steel WCB Thermostatic Steam Trap For Heating System

Quick Details:

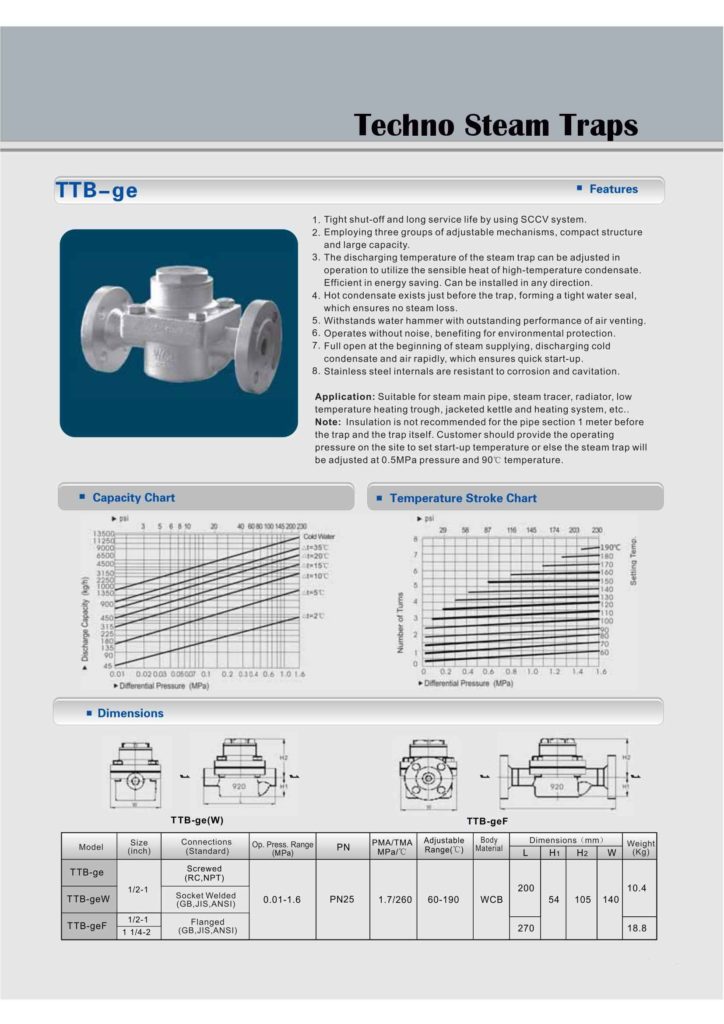

Model: TTB-ge

Size: 1/2″ – 2″

Body Material: WCB

Connection: Flange & Screw & Socket Welded

Certificates: ISO9001 & API

Water Seal, Low Steam Leak

Tight Shut-off & Longer Life

Three Groups of adjustable Mechanisms

Adjustable Discharge Temp.

Water Seal, Low Steam Leak

Design Pressure: PN25

Pressure: 0.01 – 1.6 Mpa

Material: Casting Steel WCB

Temperature: 425℃

Working Media: Steam, Condensate, Water

End Connection: Flange, Screw & Socket Welded

weight: 10.4-18.8kg

Model Number: | TTB-ge |

Standard or Nonstandard: | Standard |

Structure: | Steam Trap |

Pressure: | Low Pressure, 0.01 – 1.6 MPa |

Power: | Automatic |

Material: | Casting Steel WCB |

Temperature of Media: | Up to 425 Deg. C |

Media: | Steam, Water |

Port Size: | 1/2″ – 2″ |

Body Material: | WCB |

Connection: | Flange & Screw & Socket |

Specifications:

Thermostatic Steam Trap / Bimetallic Steam Trap / Balanced Pressure Steam Trap

TB-ge :

- Tight shut-off and long service life by using SCCV system.

- Employing three groups of adjustable mechanisms, compact structure and large capacity.

- The discharging temperature of the steam trap can be adjusted in operation to utilize the sensible heat of high-temperature condensate.

- Hot condensate exists just before the trap, forming a tight water Seal, which ensures no steam loss.

- Withstands water hammer with outstanding performance of air venting.

- Operating without noise, benefiting for environmental protection.

- Full open at the beginning of steam supplying, discharging cold condensate and air rapidly, which ensures quick start-up.

- Stainless steel internals are resistant to corrosion and cavitations. Small in size and light in weight, easy maintenance.

- Efficient in energy saving. Can be installed in any directions.

Application:

This thermostatic steam trap is suitable for steam main pipe, steam tracer, radiator, low temperature heating trough, jacketed kettle and heating system etc…

Note:

This balanced pressure steam trap Insulation is not recommended for pipe section 1 meter before the trap and the trap itself. Customers should provide the operating pressure on the site to set start-up temperature or else the steam trap will be adjusted at 0.5Mpa pressure and 90 Centigrade temperature.