TECHNO STEAM TRAPS

Innovative Steam Traps and Condensate Recovery Systems

INVERTED BUCKET STEAM TRAPS

ES8B & ESH10 & ES12N

Detailed Product Description

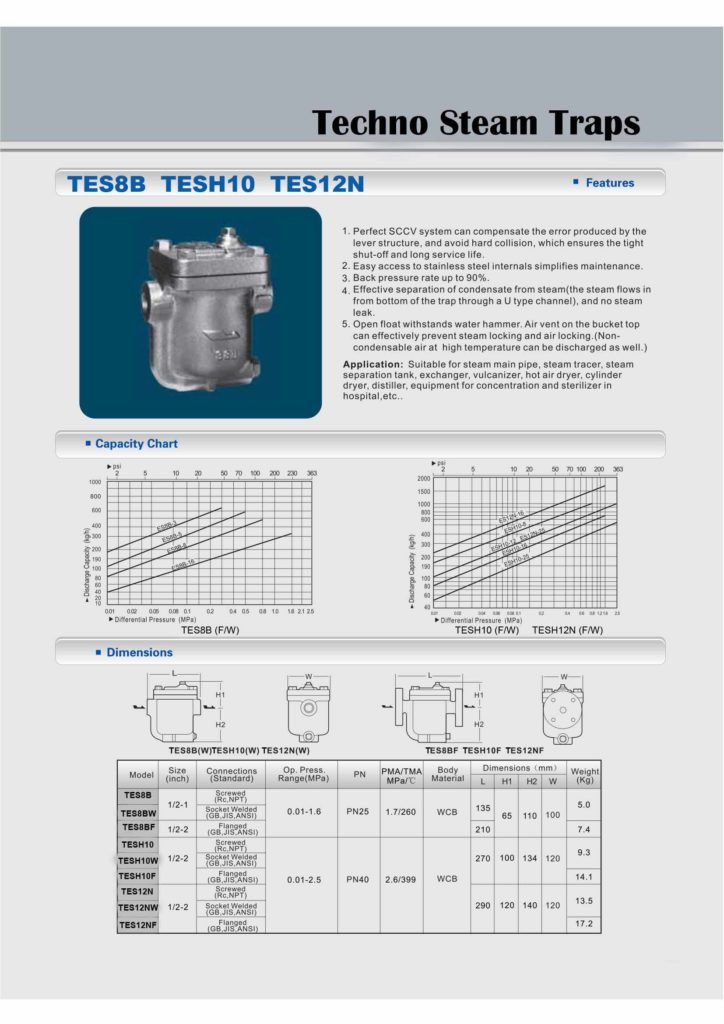

Cast Steel Inverted Bucket Steam Traps Low Pressure TES8B, TESH10, TES12N.

Quick Details:

Model: TES8B, TESH10, TES12N.

Pressure: 0.01 – 2.5 Mpa

Material: Casting Steel WCB

Structure: Inverted Bucket Steam Trap

Standard or Nonstandard: Standard

Model Number: | TES8B |

Standard or Nonstandard: | Standard |

Structure: | Inverted Bucket Steam Trap |

Pressure: | Low Pressure,0.01 – 2.5MPa |

Power: | Automatic |

Material: | Casting Steel WCB |

Temperature of Media: | Up to 425 Deg. C |

Media: | Steam, Water |

Port Size: | 1/2″ – 2″ |

Connection: | Flange & Screw & Socket Welded |

Body Material: | WCB |

Specifications

Inverted Bucket Steam Trap

Perfect New SCCV system

Stainless Steel Internals

High Back Pressure & Effective Separation

Air Vent on the Bucket Top

Design Pressure: PN25, PN40

Pressure: 0.01 – 2.5 Mpa

Material: Casting Steel WCB

Temperature: 425 ℃

Working Media: Steam, Condensate Water

End Connection: Flange, Screw & Socket Welded

Inverted Bucket Steam Trap / Mechanical Steam Trap

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

ES8B:

- Perfect SCCV system can compensate the error produced by the Lever structure, and avoid hard collision, which ensures the tight Shut-off and long service life.

- Easy access to stainless steel internals simplifies maintenance.

- Back pressure rate up to 90%.

- Effective separation of condensate from steam (the steam flows in from bottom of the trap through a U type channel), and no steam Leak.

- Open float withstands water hammer. Air vent on the bucket top Can effectively prevent steam locking and air Locking. (Non- Condensable air at high temperature can be discharged as well.)

Application:

Suitable for steam main pipe, steam tracer, steam Separation tank, exchanger, vulcanizer, hot air dryer, cylinder Dryer, distiller, equipment for concentration and sterilizer in Hospital, etc…